Schunk Sonosystems

Where reliability matters

At Schunk Sonosystems reliability really matters. Not only because our machines are situated in the production line where high reliability is needed. But also in our company culture where we strive to be a reliable partner every day.

Get my free whitepaper

Reliable partner

We strive for perfection. Not only in our machines, but also in our partnership. We love working together with our clients to help them with their challenge.

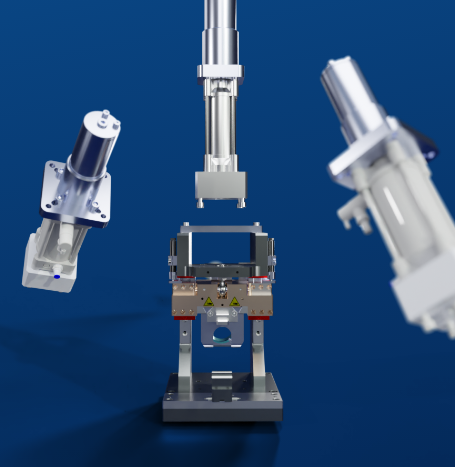

Innovative platform

We have standardized an innovative machine platform, which focuses on less complexity. Therefore, it is easy to apply fine adjustments for other requirements.

Foolproof machines

Our intelligent machines strive for 100% transparency and traceability with a log book for every weld. We are industry-leading in error detection and logging.

Worldwide service

Our extensive worldwide service consists of a central phone number, online support and training, priority emergency response and regular software updates.

Eye for details

The high-quality tooling for our machines is produced in our own state of the art factory. With this German thoroughness, we strive for a 0% error rate.

Industry track record

We are trusted by industry leaders in processes where reliability really matters.

Our known reliability

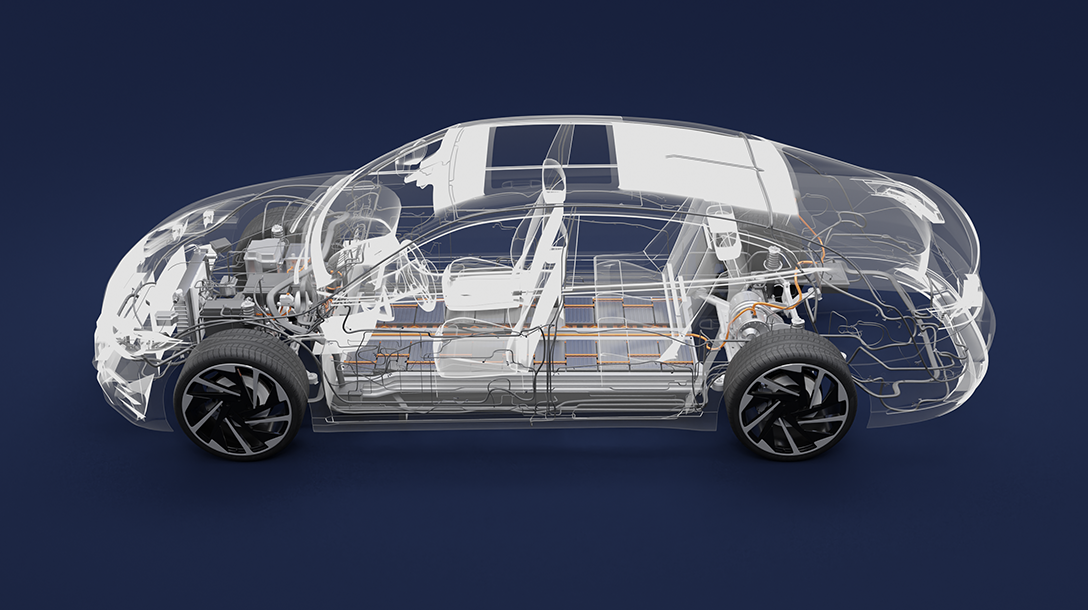

Also here for battery

You know Schunk Sonosystems for our reliability in the automotive industry. But did you know we bring the same reliability to the battery business?

In this video, you can see how our machines are part of a bigger story in automotive industry. The reliability of our ultrasonic welding systems is a key factor for successful car manufacturing.

This is why:

- We always do numerous feasibility checks before our machines leave the factory.

- We produce customized machines so that the customer has more influence on the process and the machine.

- Our intelligent machines include an error detection system, which monitors the complete welding process.

Our machines have several other advantages, that we are eager to tell you about in a personal meeting.

Success stories in the automotive industry

The requirements in the automotive industry are extremely high and we have been meeting them for many years. Discover how we manage to meet these standards again and again.

Get my free whitepaper

Maximal flexibility with the Schunk Machine Platform.

Reconfigurable within an hour.

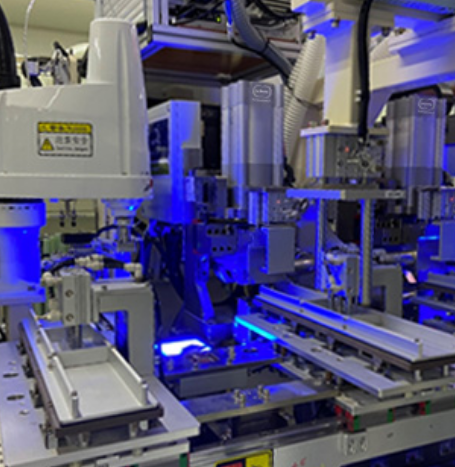

Years of experience helped us to develop a modular and reliable machine platform for automotive technologies. This provides many benefits ranging from reconfiguring a set-up within an hour, to easy operations for line operators. Our machines are known for being easy to (re)configure and their constant quality output over their long-term use.

Our machine platform is built to be foolproof and reliable, often for over 20 years.

Download your free whitepaper

What you’ll learn:

- More about the Schunk Sonosystems USPs

- Advantages of our innovative technology

- Highlighted success stories

- Which parts of the innovative platform are interchangeable

Get in touch with us

Team Battery